Precision Profiles, Unmatched Performance — Industrial Extrusion Solutions Built to Spec

When your design demands long, continuous profiles, optimized material strength, or high repeatability, extrusion is the answer. At Harbor Labs, we deliver metal extrusion solutions engineered for performance, backed by a globally distributed network of ISO-certified suppliers. We support manufacturers and OEMs in producing structural profiles, enclosures, rails, and more with dimensional accuracy, corrosion resistance, and material efficiency. From aerospace-grade aluminum to copper and brass, we help you achieve faster production timelines while minimizing waste and tooling overhead.

What Is Metal Extrusion?

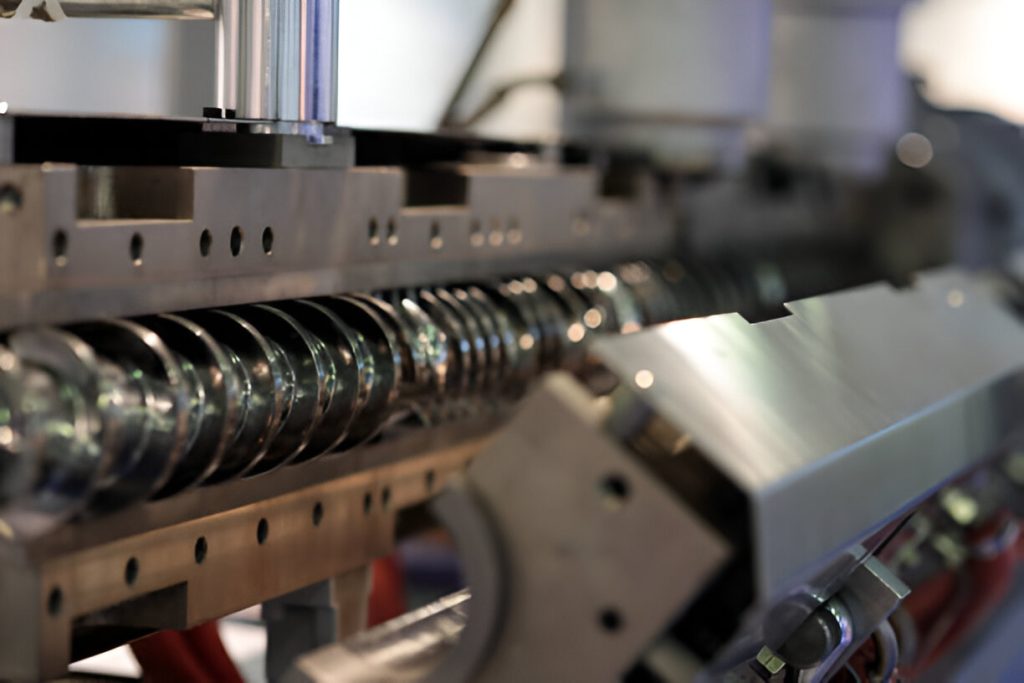

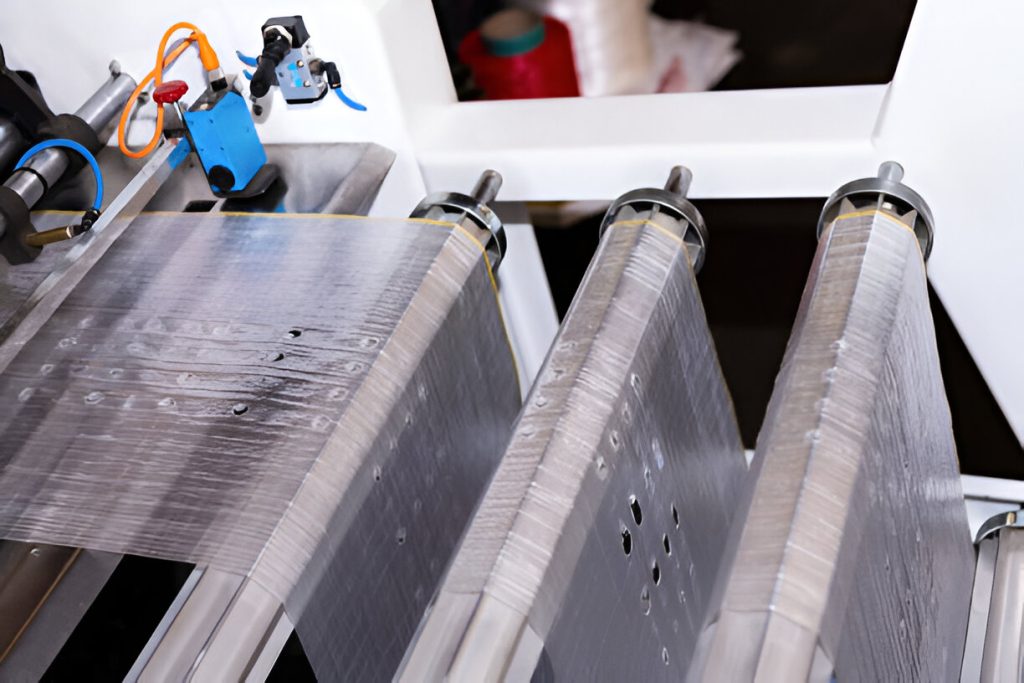

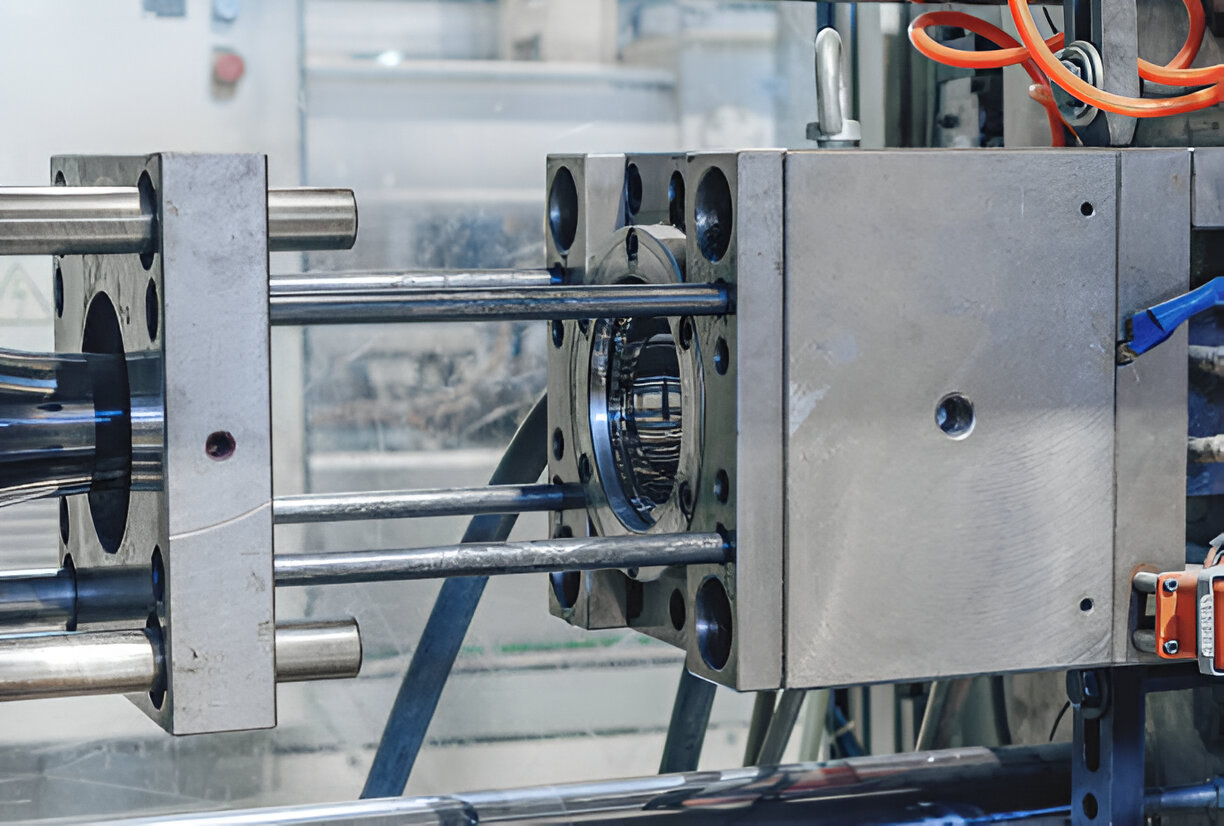

Metal extrusion is a manufacturing process where a metal billet is forced through a die to create a specific cross-sectional shape. The process works for ductile materials and results in continuous profiles of uniform geometry.

- Allows for complex, lightweight, and high-strength designs

- Ideal for long lengths of the same shape (e.g., tubes, rods, channels)

- High repeatability and low material wastage

- Excellent surface finish and post-processing compatibility

- Offers both hot and cold extrusion based on metal type and performance requirements

Why Choose Harbor Labs for Extrusion?

- Application-Specific Guidance

Whether structural, electrical, or decorative, our engineering team helps you choose the right material and shape for optimal performance. - Precision-Tooled Dies

We custom-fabricate extrusion dies that meet stringent tolerance specs — ensuring consistency across thousands of parts. - Surface Treatment Options

From anodizing and polishing to powder coating and plating, we provide finishes that enhance durability and aesthetics. - Global Supply Chain Access

Our extrusion suppliers are strategically located in Asia, Eastern Europe, and North America, giving you flexibility on cost and lead time. - Reduced Tooling Costs

Compared to machining or casting, extrusion requires simpler dies and minimal waste, making it ideal for cost-sensitive, high-volume projects. - Post-Processing Capabilities

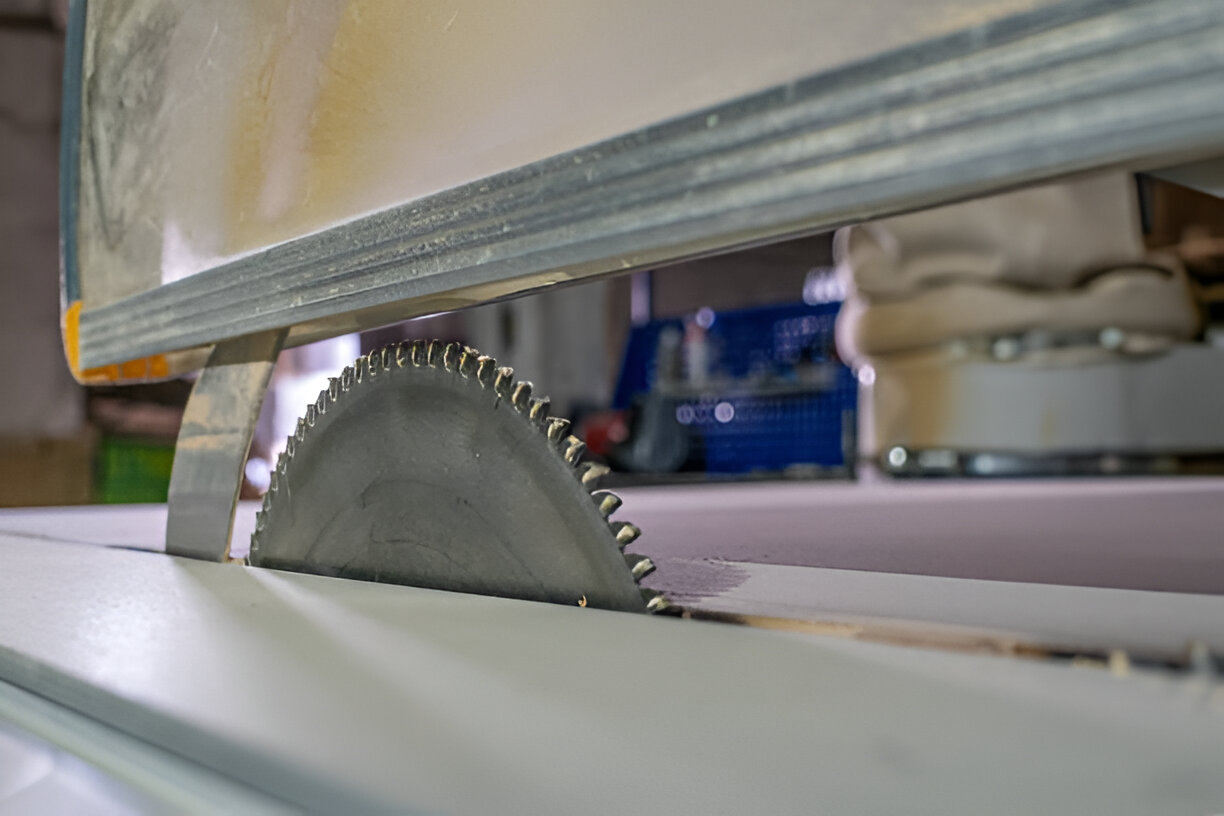

We support cutting, drilling, tapping, notching, welding, and assembly for near-finished extrusion parts — saving you time and logistics.

Extrusion Applications

- Electrical enclosures and heat sinks

- Structural framing systems

- Aerospace and automotive frames

- Solar panel mounting structures

- Architectural and construction profiles

- Tubing for fluid and gas transport

- Furniture and consumer appliance parts

- LED lighting fixtures and channels

Materials We Work With

- Aluminum Alloys (6000, 7000 Series)

- Copper

- Brass

- Stainless Steel

- Magnesium (select applications)

- Zinc

- Specialty Alloys (on request)

Extrusion Process Types

- Hot Extrusion – High ductility materials like aluminum and copper

- Cold Extrusion – Better surface finish, dimensional control, used for steel

- Direct Extrusion – Simple profiles with excellent strength

- Indirect Extrusion – Reduced friction and material loss

- Hydrostatic Extrusion – For brittle materials and complex shapes

Benefits of Working with Harbor Labs

- Faster production cycles with low per-part costs

- Minimal machining or secondary shaping required

- Enhanced product strength through grain alignment

- Consistency across high-volume runs

- Compact lead times and reliable delivery windows

- Comprehensive quality checks throughout the extrusion lifecycle

- End-to-end supply chain and vendor management by our team