Mass-Produced Precision: Investment Castings that Outperform Expectations

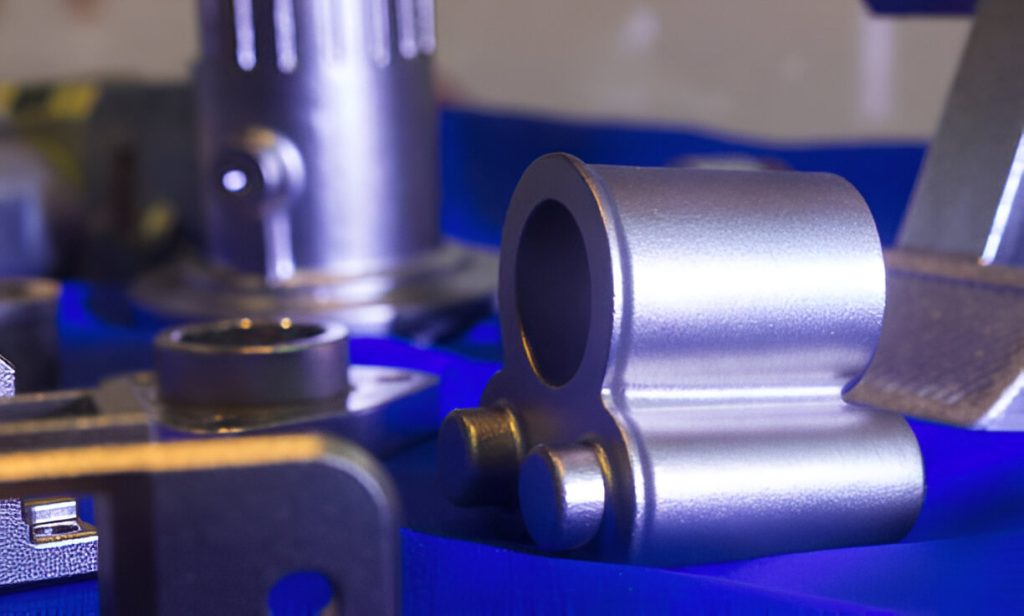

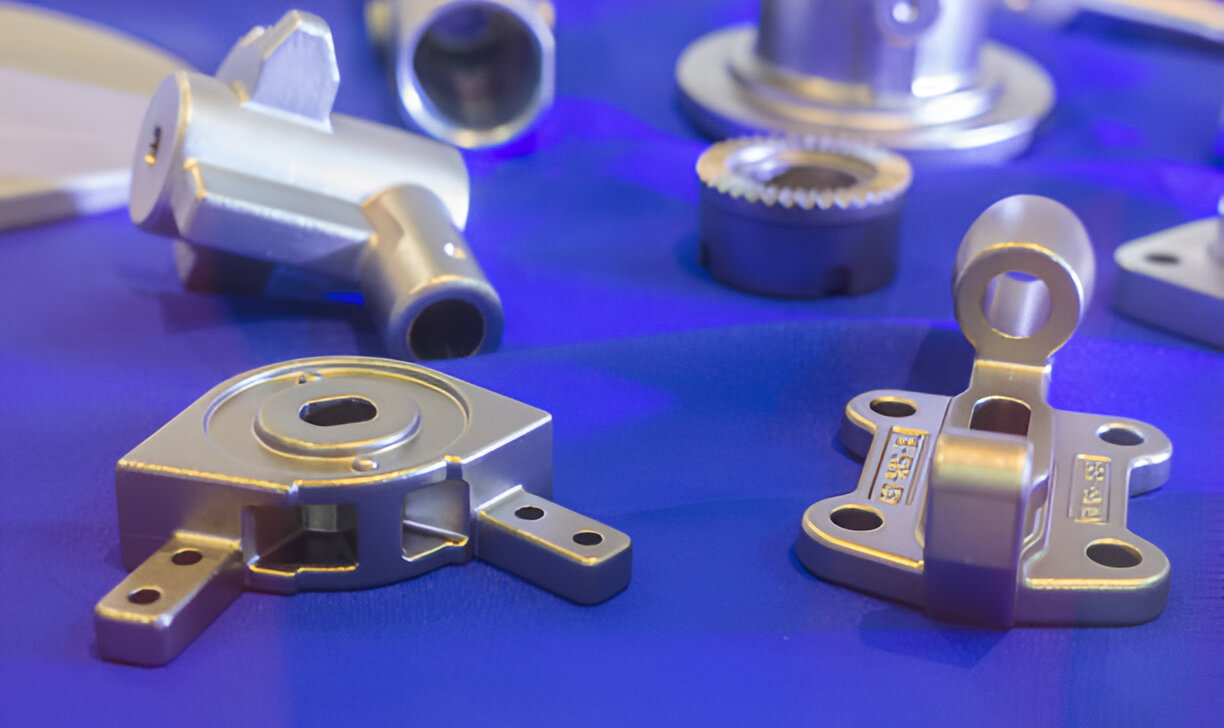

When design complexity meets volume demand, investment casting becomes the optimal manufacturing method. At Harbor Labs, we offer highly precise, ISO-certified investment casting solutions across a range of metals and alloys. Backed by engineering support and global sourcing expertise, we help OEMs and manufacturers mass-produce small and mid-size parts with consistency and confidence. Our clients rely on us for tight-tolerance, near-net-shape parts with exceptional surface finishes — from delicate turbine vanes to high-pressure tubing and intricate medical or defense components.

What Is Investment Casting?

Investment casting, also known as lost-wax casting, is a manufacturing process used to produce complex metal parts with superior surface finishes and tight tolerances. The process involves creating a wax model, building a ceramic mold around it, and then pouring molten metal into the mold once the wax is melted away.

- Suitable for intricate parts, delicate features, and undercuts

- Supports wall thicknesses as low as 0.025 in.

- Offers dimensional tolerances of ±0.003 in/in

- Eliminates the need for welding or assembling multiple parts

- Enables thin-walled, lightweight, yet strong component design

Why Choose Harbor Labs for Investment Casting?

- Precision at Scale

From small batches to large production runs, we help scale investment cast components with unmatched consistency and minimal defects. - Complex Geometries Made Simple

We specialize in intricate shapes, undercuts, and tight radii that other casting methods struggle to achieve — without expensive tooling modifications. - Surface Finish Excellence

Investment castings feature superior surface smoothness compared to sand or permanent mold casting, often eliminating the need for machining. - Dimensional Accuracy with Minimal Machining

Parts come out of the mold extremely close to final dimensions, minimizing secondary operations and speeding up the supply chain. - Global Supplier Network

Our casting partners are rigorously vetted and ISO 9001–certified, ensuring repeatable quality across thousands of units. - Faster Speed-to-Market

With rapid prototyping and scalable production plans, we cut down your product lead time — without compromising quality or cost.

Benefits of Investment Casting

- Produces highly detailed and dimensionally stable parts

- Allows for consolidation of multiple parts into one monolithic design

- Reduces machining and finishing requirements

- Enables production of parts with thin walls and complex forms

- Eliminates need for joints, welds, or fasteners

- Ensures smooth surfaces without visible parting lines

- Offers excellent material utilization with low waste

- Suitable for high-precision applications across industries

- Delivers a wide range of sizes — from tiny medical parts to larger aerospace components

- High repeatability across large production volumes

Common Applications

- Aerospace: blades, housings, nozzle guides

- Automotive: turbocharger wheels, rocker arms, gearbox components

- Medical Devices: orthopedic implants, surgical tools

- Industrial Equipment: valves, pump impellers, heat-resistant parts

- Defense: sighting systems, weapon housings, brackets

- Oil & Gas: precision tubing, couplings, and pressure-retaining parts

Materials We Work With

- Carbon Steel

- Stainless Steel

- Nickel Alloys

- Ductile Iron

- Grey Iron]

- Cobalt-Chromium

- Superalloys (on request)