Precision Begins With Tooling

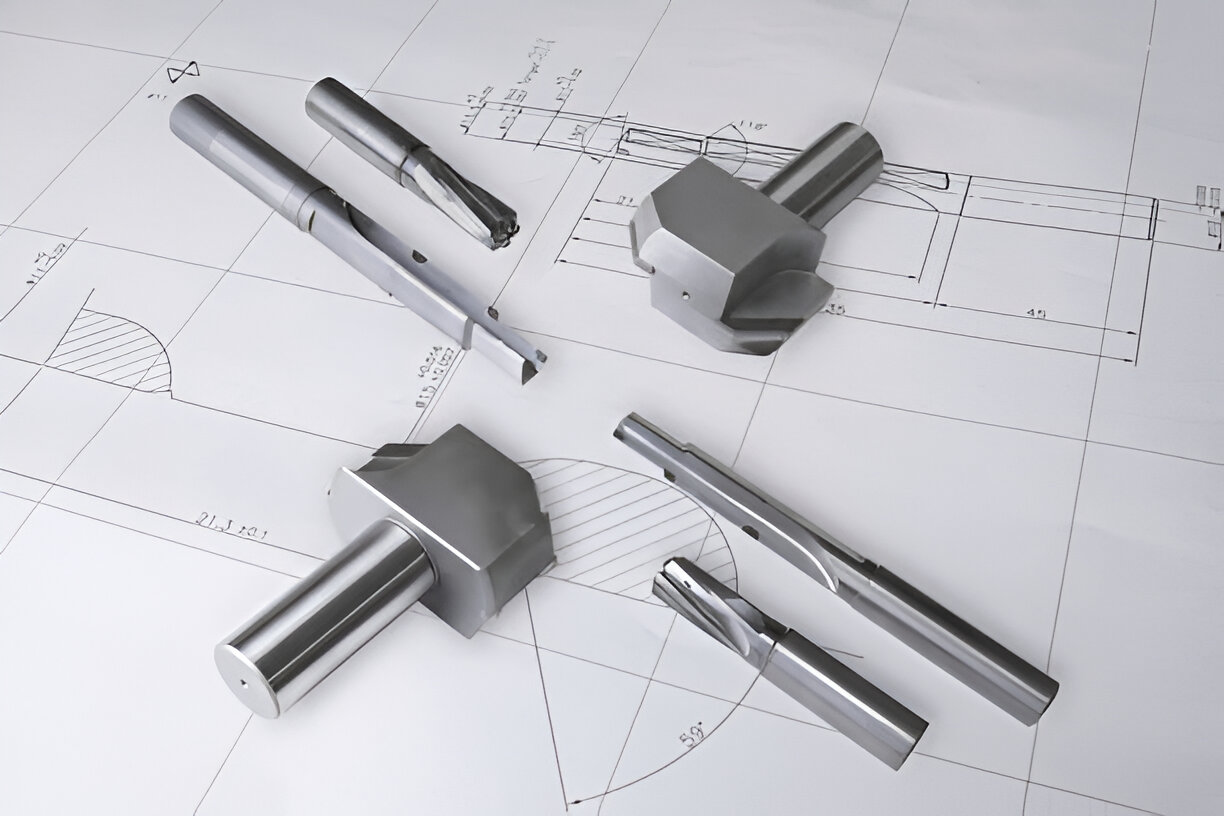

In manufacturing, tooling is the foundation of repeatable, high-quality production. At Harbor Labs, we bring over 25 years of tooling design expertise to the table — supporting our clients with customized, precision-driven tooling systems that power efficient, scalable production. Whether you're producing aluminum die castings, forged components, or precision-machined parts, our engineering team partners with you to design the right tool for the right outcome — minimizing errors, reducing cycle times, and optimizing cost-per-part. We use industry-standard platforms and simulation tools such as: 2D / 3D AutoCAD SolidWorks CATIA ProE FEA (Finite Element Analysis) Mold Flow Analysis (Magma, ProCAST) Our in-house engineers and tooling experts collaborate with offshore suppliers to align design intent with manufacturing capability — ensuring a seamless transition from digital model to physical part.

Why Harbor Labs Tooling Stands Out

- Customer-Approved Designs:

All tooling is designed and reviewed in close consultation with your team — ensuring form, fit, and function are verified before kick-off. - DFM-Driven Engineering:

We optimize for manufacturability and durability, so your tool performs longer, with fewer changeovers and adjustments. - On-Ground Oversight:

Our engineers are present during tool manufacturing and trial runs, ensuring dimensional accuracy, proper gating, and defect-free samples. - Lifecycle Monitoring:

From initial tool build to production handover, Harbor Labs tracks every stage of the tooling lifecycle and maintains detailed logs for repeatability and audits.

Simulation-Backed Tooling Precision

Before a single mold is cut, we simulate:

- Flow, cooling, and solidification

- Die stress and thermal fatigue

- Potential shrinkage, porosity, or warping

- Part ejection and cycle time efficiency

This allows us to proactively eliminate issues that could affect production performance — saving both time and cost in the long run.

Flexible Across Volumes & Processes

Whether you’re producing 10,000 or 1 million+ parts, our tooling design scales across:

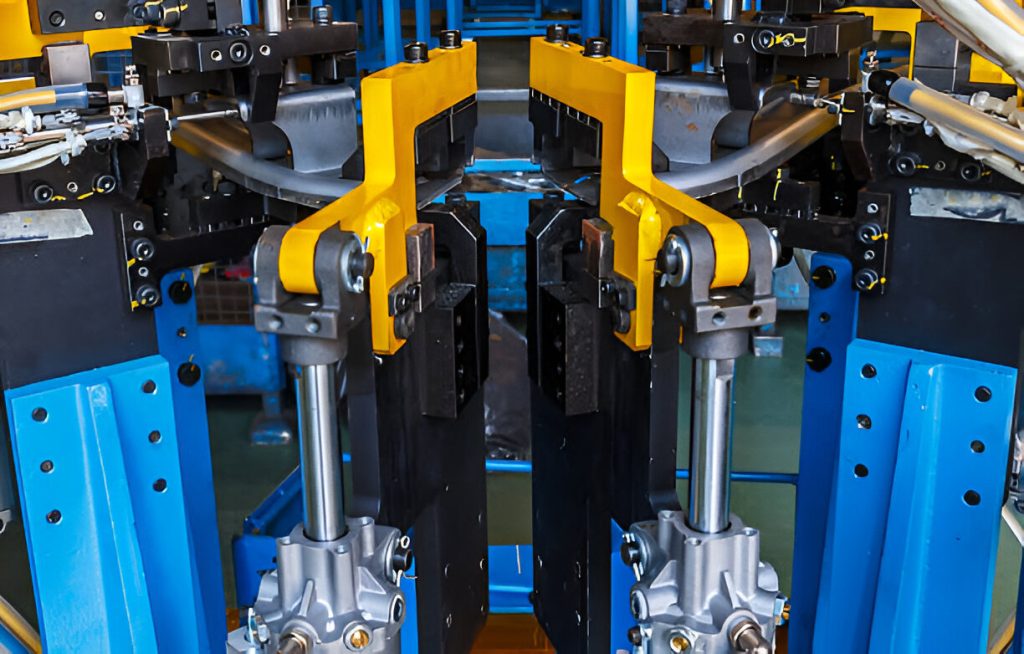

- High-volume die casting tools

- Medium-run stamping dies

- Precision forging dies

- CNC workholding fixtures

- Custom jigs & gauges for QA/QC

Our goal: maximize tooling ROI while minimizing setup delays and downstream rework.